Optical fiber sensors allows measurement under harsh environmental conditions – such as acidic. They are resistant to strong electromagnetic fields and to high temperatures – they allow measurements up to 1000 °C.

Optical sensors are small, so they can be used for very precise and spot measurements of selected quantities.

Exerci tation ullamcorper suscipit lobortis nisl aliquip ex ea commodo non habent claritatem insitamconse quat duis autem Exerci tation.

Our team members have extensive experience in photonics and electronics. We’ve cooperated with:

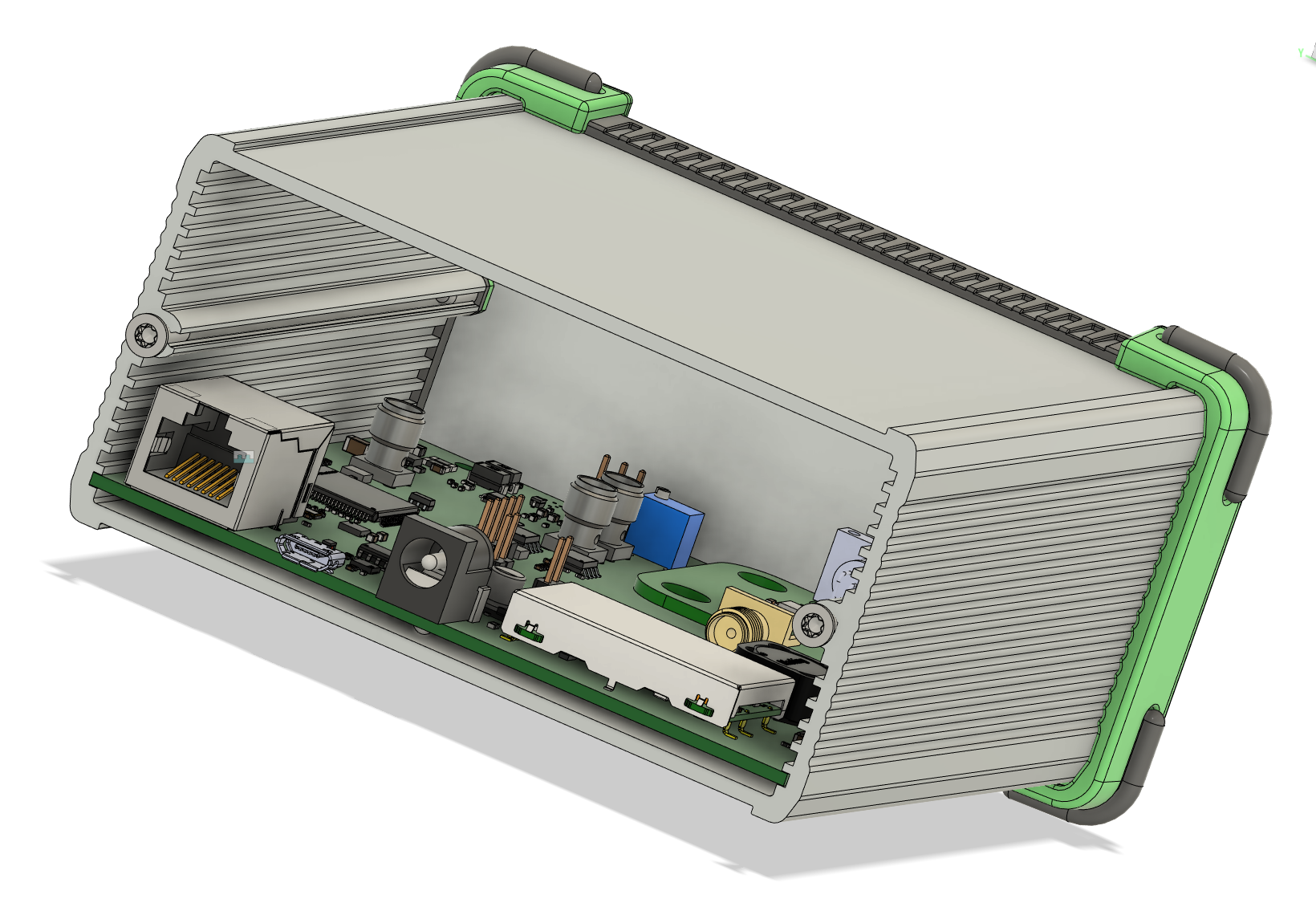

With the most advanced device you can measure different quantities with a speed up to 100 000 times per second.

Each use case is different, so we developed a flexible solution – from one sensor to a thousand.

We’ve worked and cooperated with the best research institutions around the world.